Kupar Pump

Recommendations on Pump Selections

The criteria to be considered in the selection of the type and size of Kupar gear transfer pumps are generally given below. For more detailed information and confirmation of the accuracy of your pump selection, it would be useful to contact our company.

Viscosity is one of the most important criteria in pump selection. The viscosity of the material is the most important variable in the selection of the pump type, the selection of the speed, and the production and assembly tolerances of the pump and the determination of the working gaps. For KUPAR GEAR TRANSFER PUMPS, there are 4 important points to consider when choosing a pump.

Pump Type: The general principle is to use helical gear pumps for fluids with low viscosity, that is, good fluidity, and internal gear pumps for fluids with high viscosity, that is, low fluidity.

Pipe Diameter: The maximum material flow rate that can be transferred from each pipe diameter, again considering the viscosity, is determined. While designing the system, these criteria should be calculated, and if possible, pump selection should be made before the installation pipe diameter is determined. Otherwise, the maximum flow rate that can pass through the pipe diameter of that installation must be used.

Speed: Viscosity is the main criterion, as the fluidity decreases, the speed should be reduced, and as the fluidity increases, high speeds should be preferred. Maximum 1500 rpm pump speed is used in gear pumps. While pumps rotating at 1000 rpm and 1500 rpm are directly coupled to the electric motor, pumps rotating at 500 rpm and lower are mounted directly to the electric motor with V-Belt or directly to the reducer.

Pumping Cavity: Pumping cavity are adjusted during manufacturing and assembly according to the specified viscosity value. For which material the pump working gaps are adjusted, the pump should be used for that material or for fluids with approximately the same viscosity values. Otherwise, the pump may be jammed or it may not provide the specified flow and pressure values.

Kupar Pump

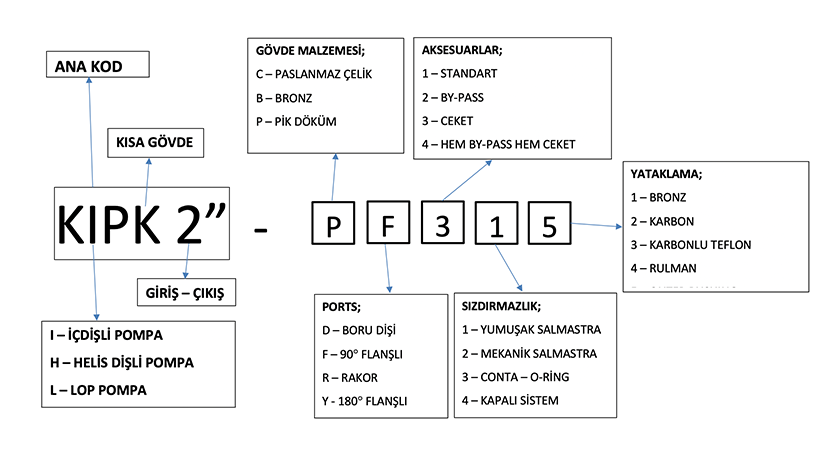

Coding System